Use the finest genuine leather for clients' products

Usually we use the first layer cow leather for our partners, it is top quality, such as oil wax leather,vegetable tanned leather,calfskin,lambskin,crazy horse leather,imported Italian leather etc.

Marking the leather

Every leather have some defective parts, we need to make some marks to avoid to use them in the next processes, to confirm finest leather parts to be used.

Cutting leather

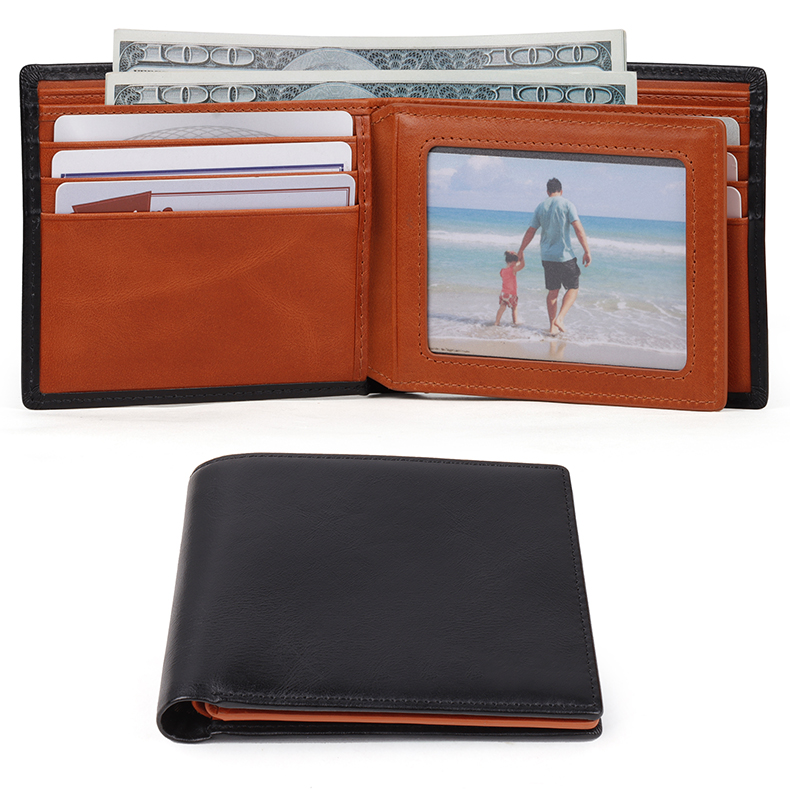

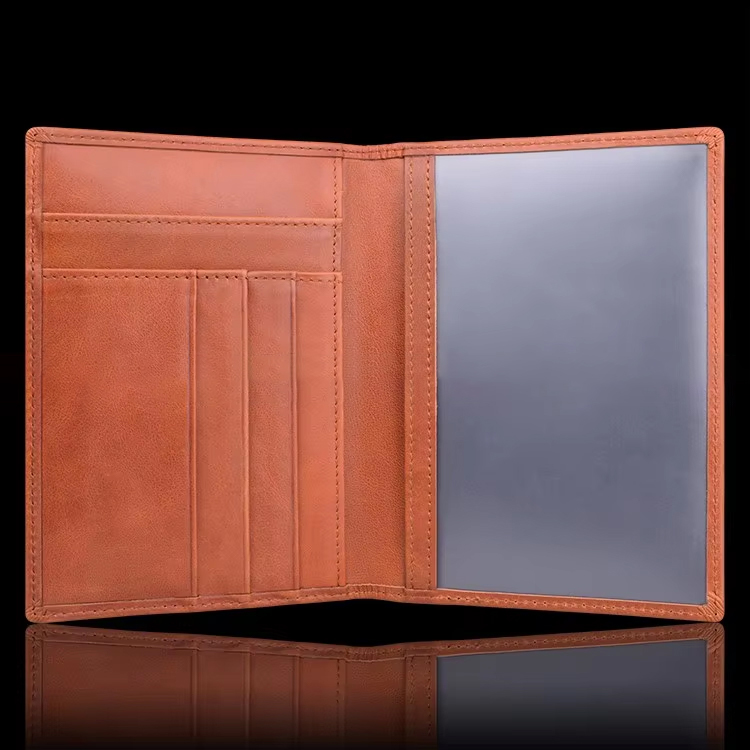

For a leather phone case, iPad case, wallets, card holders, it usually has several dimensions, We choose the best part in a leather, and make some marks to decide which part can be cut to use.After cutting to different dimension, different part has different process step, such as some will be skived to thinner, around 0.35mm-1.20mm thick for different use.

Inner material and Assembly

For inner material, we use real microfiber, imported card board, PC board, glass fiber board, magnets etc. These are the basis of our product quality. When each part prepared, we need to fit all part together and be ready for next steps.

Nice stitching

We use precise sewing machines, these machine can meet all kinds of sewing style, we will use different sewing style for different product or according to our partners' requirement, such as chain stitch, straight stitching, lock stitch, zigzag stitch and so on.

Adding Your LOGO

You can have your logo/label on the product, such as embossing/debossing, silk printing, laser cutting, metal logo etc. Usually embossing logo is free. Check examples below for your reference.

Quality Checking

When all process finished, the products need to be checked again one by one before packing and shipping.